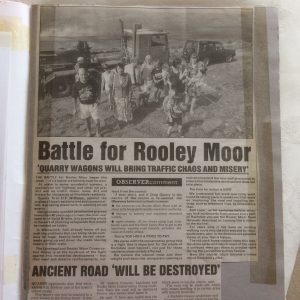

Coal mining

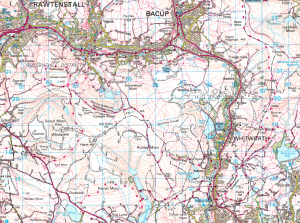

Coal was in abundance throughout the area. You can find more information through the NORTHERN MINE RESEARCH SOCIETY which is dedicated to the preservation and recording of mining history.

The following is reproduced with the kind permission of the Rossendale Collieries Facebook group.

Brandwood Coal.

This is not meant to be definitive nor deep, just an overview of coal mining on the moor.

The more you study mining on Rooley Moor, the more you understand that it wasn’t just a small cottage industry. The pits were small, but that is partially due to land ownership and royalties. If you only have a certain area to lease off one land owner then the size of the pit is thereby defined by the boundaries of the land. Parts of Brandwood Moor was enclosed so as to have ‘owners in common’ in that a number of parties had shares in a portion of land but there would be majority share holders and lesser ones which affected royalty payments. This was the case with part of Brandwood Lower End Moor.

The coal seams were thin but that should not make too much of a difference in the long run and the coal quality was certainly adequate for steam raising and domestic use. Without the coal mines on Brandwood and Rooley Moor the development of the mills of Cowpe would have been different without the local supply of coal. Coal was, besides labour, the biggest outlay for any mill so having coal on the door step and the mill owner even owning the pit could be the difference between profit and loss. Transport was very expensive and a mill or quarry owner who could produce coal at cost price within a mile or so of his works had a head start over his competitors and just imagine the effort of getting all that coal up onto the fell top for all the steam driven equipment in those quarries.

Geology.

The high upland, believe it or not, contained the Lower coal measures. To our knowledge 4 different coals were worked on the moor in ascending order:

- Holcomebrook coal 15”. The lowest coal worked. It was worked at Hugh Mill for 12 months. The coal was also worked behind Cowpe Mill although nothing is known about these particular workings except they are noted by Joseph Dickenson the first mines inspector. The Holcomebrook was also worked at Cheesden bridge and this is the most successful of the workings although on the outlier of this article

- Sandrock mine 15”. This was the main seam worked on the moor due to its abundance

- Lower Foot mine 1’. This was worked at the top of Walstead Clough as part of Old Sink colliery at least 5 acres were worked. It could be also possible that it was worked from a drift by the side of Rooley Moor Road at Bare Rake, just below the top road into Cragg Quarry but this cant be said for certain.

- Lower Mountain mine 22” This was low for the Lower mountain mine as it was usually a yard. It is found near the summit of the road at Old Sink but is cut off by the 80 yard fault. It is quite a long thin strip that runs south west towards Withens. Just South west of here is an extremely small area of outcrop which has probably been exploited with no known records.

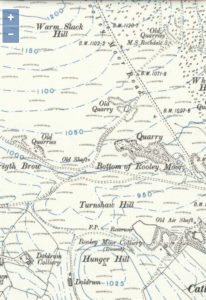

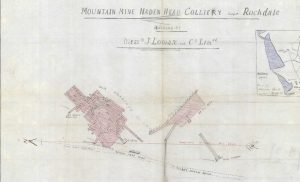

A further area was worked from the Rochdale side of the moor at Rooley Moor Colliery, Whimsey, Naden Head and Greenland. The coal crops out both on the Broadley side of the hill and the Naden valley side but a 60 yard fault cuts the take in two. Whittle Pike is circumnavigated by an outcrop of the Lower Mountain and this has been worked but by whom and when we do not know.

The major fault which runs up the Cowpe valley and affects the coalfield has a throw of 80 yards to the South West. It cuts through Cowpe reservoir and Rooley Moor on Old Sink Slack. To give you an idea of the throw; Brandwood and Rakehead Quarry work the same stone as Cragg Quarry and yet observe the difference in levels. One consequence of the fault is that it causes the Sandrock mine to outcrop on two different levels. At Brandwood Lower end the Sandrock crops out in Helm Clough and runs along the bottom of the moor above the quarries and from Heights Farm it turns South towards Intake where it follows the bottom road into Cragg Quarry until it terminates against the 80 yard fault at Part Bank. The upper outcrop is above the top road into Cragg Quarry and runs around Hailstorm Hill above Cragg Quarry and back above Ding Quarry till it meets the fault again. Three major North / South faults affect the coalfield on the Rochdale side, causing things to be much more complex.

The Collieries.

This is a very brief and concise list of the collieries, starting from Helm Clough and working around the moor.

HELM CLOUGH COLLIERY – Sandrock mine. Situated on the east side of Helm Clough and worked by James Hardman who owned Greens Quarry and Acre Mill. Coal was sent down an incline in Helm clough to the quarry and down to the mill. The pit was working in 1851 and worked on till 1901. Hardly anything is known about it apart that during the mid 1890’s it employed 20 men underground.

BUNKERS HILL/GREENS MOOR COLLIERY – Sandrock mine. Sittuated above Bunkers Hill farm it existed in antiquity. Inspectors reports name the pit from 1851 and it worked until 1865/66 by the Munn Brothers, the well known local industrialists. Horses and Donkeys were used underground for haulage and the pit worked up the west side of Helm Clough. Richard Siddal briefly re-opened the pit during the 1890s.

COLLIERY ON 1844 MAP. This was next to Bunkers hill and appears on the first OS map and was into the Sandrock mine. Nothing has yet come to light about these old workings. There were two stone arched drifts about 2’6” high. There is reason to believe that the Brearleys used these drifts when they commenced Brandwood Moor colliery during the 1860’s.

BRANDWOOD MOOR COLLIERY (Brearleys) – Sandrock mine. This was opened during the mid 1860s possibly from the two aforementioned drifts. A large haulage drift was later driven further to the west and an incline constructed down to the staith at Blackwood. There was also a brick kiln at the pit and clay was worked. The pit closed C1908 due to hitting an underground stram and no sufficient investment to cope with the problem. No plans of the pit have ever come to light but it is belived to have worked a large area of coal.

BRANDWOOD MOOR COLLIERY (Ashworths) – Sandrock mine. Worked from 2 drifts between heights farm and Brandwood Moor farm. It was worked by the owners of Cowpe Mill and worked from 1851 through to the mid 1870’s.David law later worked a small patch of coal from the north drift before abandoning the pit in 1886

INTAKE COLLIERY (Henpeck) – Sandrock mine. A very old pit with still quite visible remains. It was besides Rooley Moor Road almost opposite Intake Farm. It could possibly have been worked by Ashworth and Livesey of Cowpe Mill during the 1830’s/40’s. John Woodhead worked the pit from the early 1860’s and his brother was killed there. David Law later took over the pit during the 1870’s and he appears to have been working small areas left by previous owners. There are a group of small drifts further up Rooley Moor Road marked as ‘Old Colleries’ on the 1844 map. Nothing concrete is known about these small workings.

PART HOUSE COLLIERY – Sandrock mine. On the 1844 map this can be seen straddling the track that eventually lead up into Cragg quarry. Evidence points to this being worked by Thomas Livesey of Cowpe Mill was working it during the 1830’s

PART BANK COLLIERY – Sandrock mine. This was the last colliery along the track before the 80 yard fault was hit. David law worked it in the 1870’s as he was working Intack. The drift was a substantial stone arch and so could have been driven before David’s tenure perhaps when the Livesey’s ran the pit. From research it would seem that David had been a normal collier and worked in these pits before taking them on himself when the other owners had given up.

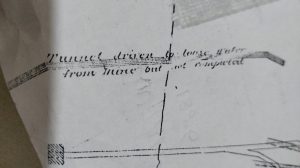

If we go back to Rooley Moor Road and progress up it for some way and as we near the top road into Cragg Quarry there are two drifts into the field on the right known as Bare Rake. Nothing is known of them except folklor that they were last worked in the 1926 strike. The lower one could quite well be into the Lower Foot mine and wonder if any of them were driven as drainage levels for Old Sink Colliery.

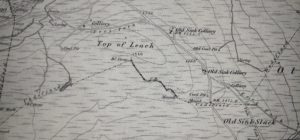

MILL MOOR COLLIERY – Lower Mountain mine. Just above the top road into Cragg quarry and marked on the 1844 map as ‘Colliery’. It could either be part of Old Sink colliery or Mill Moor colliery owned by the Ormerod brothers in the 1850’s, but doubt the latter explanation. Just a little to the west the 80 yard fault is hit.

MILL MOOR COLLIERY – Sandrock mine. Next to the west on the 1844 map is marked ‘Coal Pit’. This was developed probably by the Ormerod brothers and worked during the 1850’s. Joseph Dickenson marks the area worked by the colliery on his map.

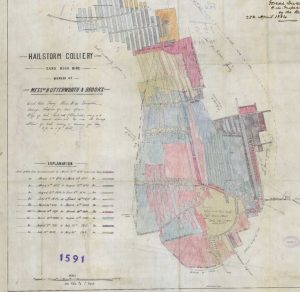

CRAGG COLLIERY – Sandrock mine. Situated further west and above the quarry, the pit heap is still very visible. This was worked by Butterworth and Brooks and the coal went to the quarry. It met up with hailstorm colliery which came through from the other side.

OLD SINK COLLIERY – Lower Mountain mine and Lower Foot mine. This is where things get complicated. Old sink dates back certainly to the 1820’s perhaps even before. The 1844 map clearly labels 2 shafts. In 1854 the pit is in mines inspectors reports as being owned by Townsend Hargreaves and Barlow who had clearly worked it for a number of years, however there is no proof of where they worked it. At present, the favourite location could be the two named shafts on the map and possibly the drift at Mill Moor. Mr Howarth worked the pit from the 1830’s from the shafts labelled ‘Colliery’ and ‘coal pit’ on the map. A track leaves Rooley Moor Road and heads off down towards Walstead clough and ther is the remains of an old shaft here that is not on any map. Down in the clough, the Ormerod brothers had a level into the lower mountain and a shaft down to the lower foot and they worked these during the 1850’s. Going back to Rooley Moor Road and starting to climb out of Old Sink Slack just at the point that the cobbles start. A track leaves the moor to the very visible remains of a shaft, This was sunk by the Lomax’s and traded as the Rooley Moor Iron Co. This was sunk C 1866 and known also as Old Sink which they worked in conjunction with Greenland.

BARTLE COWM – Lower Mountain mine. Worked by Zachariah and James Howarth. The pit is shown on the first OS map and the shaft can still be seen today. Lower down the hill to the south east are at least 3 drifts joined together by a series of old tracks. The east most is marked on the map as Withens Meadow Coal Pit. Were they are all linked, literally as workings and also as to ownership?

HALL COWM AND KRUGER – Sandrock mine. These pits were all worked by Henry Heys for the quarries. They worked almost from the northern side of Walstead Clough right the way across the top of the Cowm Quarries to beyond Robin Hoods Well Clough . The Kruger pits were working in the 1890’s and Hall Cowm closed in 1944. Next to Walstead Clough it looks like there has been a drift and further earth works run down the Clough. The Sandrock further South, above Withens Farm was worked from Withnens Colliery and the coal sent down to Hall Fold.

HAILSTORM COLLIERY – Sandrock mine. Situated above Ding quarry with an incline from the pit down to he quarry. It was owned by Butterworth and Brooks and ran for the benefit of the quarry. The site was destroyed by building those turbines. The pit connected underground with Cragg colliery.

GREENLAND COAL PIT – Sandrock mine. Situated behind Prickshaw Dam and appears on 1844 map. It was quite a deep shaft though the actual depth isn’t known. The pit but it was abandoned by 1850.

GREENLAND COLLIERY – Lower Mountain mine. Owned by John Lomax and Co and run in conjunction with Old Sink. It was open in 1872 but not listed after 1878. The site appeared to be at the top of Broadley incline where it branches off to Bagden Quarry, there is a large depression that certainly looked like a drift. Dickenson had it marked on his map in that position and marks it also as the crop of Lower Mountain mine. A further drift is to be found to the SE nearer Whimsey Pit and it looks like they were running pillars out of that pit.

ROOLEY MOOR COLLIERY – Lower Mountain mine. This was situated near Cat stones and consisted of 2 drifts intothecoal driven in the 1950’s by three lochan men who also opened up a drift on Hunger Hill and tried Scout Moor Colliery also. The pit just looks like it went a few yards.

WHIMSEY COAL PIT – Lower Mountain mine. Obviously an old pit dating before 1850 and taking its name from the method of winding. The shaft was 60 yards deep.

ROOLEY MOOR COLLIERY – Lower Mountain mine and Sandrock mine. Situated at the bottom of Rooley Moor, the site can still be clearly seen. The pit ran over 50 years and was operated by Lomax. It consisted of at least 2 shafts near the bottom of Rooley Moor Road and by the beginning of the 20th century was almost exhausted. It was also connected underground to Hunger Hill Colliery and most of it’s life worked the Lower Mountain mine which was about 22 inches thick. There was an underground drift into the Sandrock mine also where it met up with Hunger Hill and Doldrum Collieries.

Doldrum Colliery – Sandrock mine. Worked and owned in 1896 by John Lomax. John Scholes manager, John Shorrocks under-manager. 20 men underground and 3 on surface. This rose to 27 underground by 1901 and later to 31. There are conflicting reports that it was discontinued in 1906 yet employed 25 men and 3 on surface. It was abandoned by 1910.

The following is reproduced with the kind permission of the Rossendale Collieries Facebook group.

Hunger Hill Colliery – Lower Mountain mine and Sandrock mine. A drift was driven in the 1950’s near the old Rooley Moor colliery but didn’t produce for very long. Hunger Hill itself is listed as working the in 1877 owned by Lomax and Co. 1877 manager James Lord. 1882 L.G. Robinson is manager. 1896 John Scholes manager. John Sharrock under-manager 30 men underground, 4 on surface working. 1904 discontinued.

The following occurred at Hunger Hill Colliery.

Rochdale Observer 5th August 1914

FATALITY AT NORDEN CORONER AND “A BRAVE ACT.”

On Sunday evening William Albert Kershaw, aged 16, 259, Rooley Moor Road, Spotland, lost his life through falling down a pit shaft the disused Hunger Hill Coal Pit, Rooley Moor. Deceased went there with other lads Sunday afternoon, and climbed over a wall six feet high which surrounds the pit. One of the flags covering the shaft gave way under deceased’s weight and he fell down. And dropped on a landing 45 yards below and was instantly killed. It was not until half-past nine at night that the body was removed from the pit. P.S. Benson of was informed the occurrence and went to the shaft with a large piece of rope. Many persons had assembled there and one them, Mr. James Henry Fleming, a fireman at East Knowl Colliery, agreed to go down the shaft. A rope was tied round his waist and he was lowered down the shaft and on reaching the body succeeded in raising it and ‘bringing it up with him.

THE INQUEST.

Mr. P. N. Molesworth, county coroner, held the inquest the body at the Council Offices yesterday afternoon. Mr. F. N. Siddall, inspector of mines (Bolton), and Mr. J. Lomax (John Lomax and Company Limited), the owners of the disused Hunger Hill Colliery were present. Samuel Schofield, a cotton weaver, stepfather of the deceased, identified the body and said the youth left home about half-past one Sunday afternoon. Witness could not say whether deceased had been to this coal pit before, but knew he had been on. the moors-. William Albert Holden, aged 19, a warehouse hand, of Balfour Road. Spotland, said he and another lad met the deceased about two o’clock Sunday afternoon, and they all decided to go to the Moorcock for a walk. Instead of going to the Moorcock, however, they turned over the moor, rambled about there, and finally reached Hunger Hill Coal Pit. It was then a quarter to five. They went to the pit shaft. A portion of the top of the wall around it had been knocked down.

- The Coroner : It must have been done by persons with very little brains. The wall was placed there for public protection.

- Continuing’- witness said deceased climbed over the wail, and then there was a splash as if something heavy had fallen into water. Witness climbed over the wall. Only half of the pit mouth was covered with flags.

- The Coroner : Were you not afraid that the other flag would go down while you were on it?

- Witness: I risked that. I looked down the shaft and shouted deceased’s name, but got answer.

- Half of the covering of the shaft must have gone down with him?

- Yes. sir.

- The Coroner: It is very evident what happened. “I hope,” said the Coroner, addressing the witness. “That it will be lesson to you to have nothing to do with things you know nothing about.’’

James Henry Fleming, a fireman, 46, Moss Row, Norden. described how he descended the shaft on a rope and recovered the body. Deceased was lying dead on his left side on a landing 45 yards down. Witness tied piece of rope round the body and brought it to the top of the Pit. The flag which had fallen with the deceased was heavy. It was resting on his legs. P.C. Armitt described the injuries to the deceased. There was a deep cut the back of the head the left side and the neck was dislocated. There were also small bruises the body and three punctured wounds on the right knee.

- The Coroner: Are you troubled by boys doing mischief at this pit?

- Witness : No, sir. It is the first time I have known them go there.

A DANGEROUS THING.

Addressing the jury, the Coroner said there was a good wall around this shaft and thought it would have been safer have to have left the pit itself uncovered. Had the pit been left open no one would have gone over the wall. The jury returned a verdict of “Accidental death.’* Hodgson drew attention to the plucky conduct of Mr. Fleming, and stated that he spoilt a new suit of clothes in going down the mine And effort should be made to reimburse him the cost of the clothes.

- Mr. Schofield: The lad’s mother and father thanked Mr. Flemming for what did. “I think he did a brave act, I will give a sovereign towards the cost of the clothes.”

- Mr. Lomax: I will pay the remainder.

- The Coroner (to the jury): “Do you wish your appreciation of Mr. Fleming’s brave act be put on record?”

- The jurymen stated that they did, and Mr. Molesworth said it should be done.

- A vote sympathy was passed with the relatives of the deceased.

The following is reproduced with the kind permission of the Rossendale Collieries Facebook group.

Naden Head Colliery – Lower Mountain mine. In 1901 a small drift was being driven at Naden Head to exploit a small patch of reserves near Rooley Moor Road. There was a terrible accident driving one of the drifts and the two men driving it were killed and not found till the next day.

The following was reported about the incident:

Manchester Couriers and Lancashire General Advertiser October 22 1901.

ROOLEY MOOR PIT DISASTER. COLLIERY COMPANY CENSURED AT THE INQUEST. INSUFFICENT SUPERVISION.

Yesterday afternoon, Mr. F. If. Molesworth held inquest at the Black Dog Hotel. Lane-head. Norden, near Rochdale, on the bodies of Robert Buckley, aged 34. collier, of Rake Bridge, Rochdale, and Edward Holt, 27, collier, Birches, near Whitworth who were found dead in a drift at Rooley Moor new coal pit, at Naden Dean, on Saturday morning. On Thursday morning Buckley and Holt went to their work at this new colliery in making tunnel, and were the only persons who were employed making the drift, was that day, about 50 yards in length. On Thursday evening they did not return home, and on Friday morning their wives informed Mr. James Lord, the manager of a colliery in the neighbourhood.

About 20 colliers set to work to remove the fallen earth, and shortly after midnight. Robert Buckley was discovered with his back, ribs, and both legs broken. At noon on Saturday morning the body of Holt was found. There were wounds upon him and it was evident that he had been smothered. Mr. J. Gerrard, H.M. Inspector of Mines, was present, was also Mr. J. Hartley, chairman the Rooley Moor Colliery Company. Mr. David Thompson represented the relatives of the deceased.

Anxious All-night Vigil.

Elizabeth Buckley, widow of the deceased man said Buckley was an experienced collier. On Thursday morning he went work at half-past five, taking his breakfast and dinner with him the evening he did not return at his usual time. She waited anxiously the whole night through, and at half past six the following morning after visiting several relatives, she went, with her brother, to the pit. At the mouth there was some clothing. which she her recognised as her husband’s and raised the alarm that he was missing.

He had eaten his breakfast but his dinner was untouched, and this fact, Mr. Gerrard thought fixed to some extent the time of the disaster. He had been working at the drift for a fortnight, where he working for the witness’s father.

A fireman named William Buckley of Hollands farm Lanehead, worked at the Hunger Hill Colliery and formed one of the rescue party, said Buckley and Holt were found about twenty five yards up the’ drift, about two yards apart .Both were under debris, the nature of which was described as wet earth. There was one stone that he saw which weighed two hundredweight. Asked for his theory the cause of collapse, witness thought the slabs they had put were not strong enough, neither were the lids, which were all the slabs rested on. The walls at the sides of the drift that the man had built up as they went looked as firm as ever.

A Satisfactory Job

In reply to Mr Thompson as to weather the work was done as well as possible Buckley replied that I thought it was a very satisfactory job. Only the coupling lids have been a bit narrower, and stronger timber should have been used although the slabs may have held up better had the coupling lids under them been stronger.

Mr. Gerrard asked him if he knew thay had taken the timber from an abandoned pit further out. He said he had heard they were pulling timber out, but the coupling lids in the drift concerned appeared to be new.

- Mr. Gerrard: You did not see the piece of timber that was only inch and a half thick, that was being used as a coupling lid?

- Witness: No.

- But formed the opinion from what you did see that the timber was too thin

- Witness: Yes.

The Thunderstorm Theory

Regarding the thunderstorm, Which has been theoretically advanced that was cause of the collapse. Witness said that just before they came to the top on Thursday they heard a crash of thunder, and they were informed that it had raining very heavily it had been coming down very hard and the heavy rain may have caused the collapse. He had noticed that the earth that had fallen in was saturated to some extent with water and would cause it to fall a dead weight.

- Mr. Gerrard: And all the more reason for needing greater strength

- Yes – Continuing, from what he saw when they were getting Holt out, he thought they had got to solid ground.

A Word of Praise for the Miners

At the conclusion of his evidence Mr. Gerrard said that miners were always ready to come forward on occasions such as these and the fact that the men went with their lives in their hands and subjected themselves to such risks certainly deserves some recognition; (Hear hear from the Jury) they might easily have been buried in another collapse.

John Scholes, Manager said that the deceased men were working under Thomas Lord a Fireman. He had been down the drift since the accident and noticed that the lids were broken due to the weight upon them.

- The Coroner: Is it your opinion that the lids weren’t strong enough for the job?

- They did not know what weight would be upon them.

- The men knew what timbering was required.

- They put in according to their opinion what was required at the time.

- You think now that the timbering was to slight?

- It must have been.

- The Coroner: There was an error of judgement as to what with regard to them meeting more weight than was expected.

In Answer to Mr. Thompson the witness opined that the lids might have been a little longer at the ends.

- Was it new timber?

- It all looked good timber but it was mixture. This witness thought the accident was caused by broken ground. There were some large stones and if these alighted on the lids it would be sure to break them through.

- Mr Hartley: Have you had instructions off the company that you should have timber of a particular strength?

- Witness: I have always had whatever I wanted.

Collapsed for 19 feet.

Cross examined by Mr Gerrard. Scholes said the whole place had collapsed for 19 feet, one piece of timber having snapped like a carrot. The thinnest piece he saw would be about 1 and a half inches thick which rested on the walls for about two inches. While he noticed one pice that was not resting on anything at all. The lids were about four feet apart and it would have been better if they had been nearer.

- Proper supervision would not have prevented work like that?

- Not in such conditions as that in broken ground.

- From what you saw would you say there had been proper supervision?

- I would rather leave that one out.

Witness further stated that a stone arch would have been better than the two walls with couplings. But it was only a temporary affair as they did not expect getting much coal out of the drift.

Buckley His own Supervisor.

Thomas Lord, Fireman had to be specially brought from his home at Fairview, Lanehead, Norden as he was ill said he was last down the drift on Tuesday, he then sounded the roof as it was part of his work to make sure the place was safe for the men to work. He however, neglected to do this on the Wednesday and Thursday mornings as he was ill. He engaged Robert Buckley (one of the deceased) in his place.

- Coroner: Surly it is not the rule to let the men who do the work supervise it?

- Mr. Gerrard; Hardly.

- Witness resuming: The place had been as safe as ever he had seen one on the Tuesday. The thickness of the timber was 4 or 5 inches. He informed nobody of his illness except Buckley when they all came away together on the Tuesday night.

- Mr. Gerrard: if proper supervision had been provided then somebody would have been there on Thursday to discover this sad fatility?

- Witness: There should have been somebody there.

- Didn’t it occur to you that it was your duty to inform the manager or the Agent of your absence?

- It was my duty.

In conclusion the witness, who moved with difficulty said he was 75 years old and had worked underground for 69 years.

James Lord, manager of the Hunger Hill colliery, another old man said he was brother to the last witness whose duty it was to visit the men he had set to work in the drift. He thought the timber that had been used in the drift was to slight for the job.

The Coroner told the Jury that there had been a great deal of carelessness and mismanagement in the case of both Thomas and James Lord but weather it was gross carelessness was for the jury to decide.

Verdict.

The jury after consultation in private for a considerable time returned a verdict of accidental death in both cases. They added that sufficient supervision had not been given by the company and the company should be censured for not providing it.

Mr. Hartley said he would convey that expression to the directors and would like to endorse the remarks of Mr.Gerrard regarding the conduct of the men who had assisted on recovering the bodies of the unfortunate men.

A few notes regarding this sad accident.

It appears that the men in driving the drift were building a wall at either side of the road, probably out of stone. On top of the wall they placed slabs, or roof bars from one side to the other. To tighten the bars to the roof and to add additional support, or a bit of built in ‘give’ they were putting short pieces of wood called ‘lids, or caps’ on top of the wall beneath the bars. When weight came on to the road then the lids would squash but leave the bars unharmed on top of the wall.

The ground they were going though was broken in that they hadn’t reached the rockhead properly when the strength of the roof rock would be stable.

An almost identical accident to this occurred at Coanwood Colliery Northumberland in 1894. This time there were three men underground: 2 drift men and the Under-manager who was doing his mid shift inspection. The drawer had just gone to the surface and the other men were just about to come out for their bait when the roadway shoved and pushed the timbers out, killing James Clennitson of Alston outright, he left a widow and 10 children. Thomas Nixon sustained a broken leg and broken ribs. These men were supervised and still the accident happened, however the undermanager and drawer were there to raise the alarm.

Another interesting thing which comes to light is the Fireman at Naden head; Thomas Lord who is 77 years old and can hardly walk and is brother of the manager at Hunger Hill. He had been underground for 69 years! So he started as a six year old in 1830. It’s not exactly an easy walk from his home to the pit neither. It looks as if the two men were just seeing their time out with the pit. Rooley Moor Colliery was a very old one and was just about reaching the end of its days. Naden head drift only worked until 1904. There was a brief attempt to put some drifts into the coal during the 1950’s near Cat Stones but the venture didn’t last very long.

Cotton and Wool Production

Caldershaw Mills

Friends of ‘Heritage Green,’ Jenifer & Adrian Sutcliffe and Mark Hope have been doing a bit of research to establish where the water supply from the concrete structure on Heritage Green went to.

Here’s what they discovered:

It appears that there were some mills known as Caldershaw Mills on what is now Caldershaw Industrial Estate near where Ings Lane meets Rooley Moor Road. Samuel Heap and Son Ltd. of Caldershaw Mills, Rochdale are listed in the 1891 Rochdale Trade Directory as bleachers and dyers and as fullers and finishers, they occupied Caldershaw New Mill, which became known as Rake Bridge Mill. It is unmistakenly the building that was last occupied by First For Fitness, next to Pennine Fencing. It is lilkely they owned other buildings including a warehouse on the other side of Rooley Moor Road where there are now houses. Its predecessor or sister mill was Caldershaw Old Mill which has a Spotland address. Samuel Heap and Son Ltd also had premises at Bentfield Mill, Greenfield – 1891 Directory (Uppermill and Greenfield): Listed as fullers and finishers. We think they may have had a mill in Whitworth.

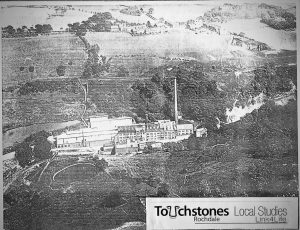

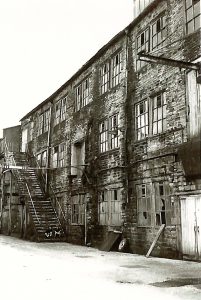

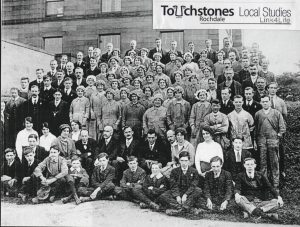

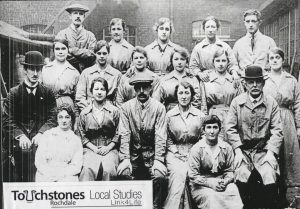

The following old pictures are from the archives at Touchstones.

Caldershaw Mills – Before Conversion:

Caldershaw Mills – After Conversion:

If you look at the existing building there is no doubt that that is what it is. We spoke to the owner of Pennine Fencing and he is aware that there was (is?) a water supply and he knew it came from a long way off and pointed in the direction of Heritage Green. We clocked the distance by road and it appears to be about 0.6 miles.

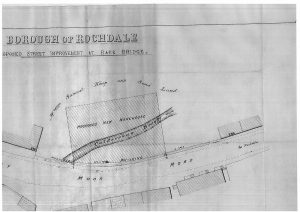

If you look in the bottom hand corner of the enclosed map Rake Bridge is marked.

Also attached is an article referring to a massive blaze there in 1963.

There is a book about the Heap family called Blue Clogs which is at Touchstones (shelf G3 reference HEA). They were obviously a wealthy family.

We are still wondering if something did go on at Heritage Green as we have to date discovered 3 millstones and it seems odd that they are on or near Heritage Green, but we may never know.

A Catley Lane Head resident suggests Wham Dam was also a source of water for Caldershaw Mills – further research is required.

Healey Hall Mill

1985 Observer Article by John Cole

We are grateful to Bernice Clifton for providing the following photographs of the mill.

Mill cottages – 1974 – Note “EWS” on the side of the cottage. We think EWS = Emergency Water Supply – Click HERE for more information.

Buildings opposite the mill – 1974

Mill lodged drained – Winter 1984-5

Lodge deepening – Jan / Feb 1987

Beginning to demolish the mill chimney – Feb 1987

Healey Hall Bottoms Mill

John Leach & Sons – Healey Hall Bottoms Mill

Pillings Mill

Pillings Mill was a factory, built in the early 1800’s, which produced gun cotton during the World Wars. It is believed the mill burnt down shortly after 1945. There are now no signs of the mill that was located in Grove Wood, close to the Facit Branch of the Lancashire and Yorkshire Railway line.

Samual Heap & Son

Smallshaw Cotton Mill

Maxim Papers – Smallshaw Cotton Mill

Spring Mill

Spring Mill was one of the oldest mills in Spodden Valley. It was built around 1810 and rebuilt in a new location in the 1890’s as a dyeing and bleaching mill for fabric. Spring Mill had its own tram to bring coal and acid to the factory and finished cloth down to Broadley Siding, where goods were tipped directly into waiting wagons on the Lancashire and Yorkshire Railway line. The railway line was constructed in 1870. Broadley Siding was also used by the quarries in the surrounding hill.

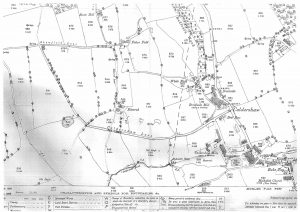

1929 1: 2,500 OS map. The 3ft-gauge tramway shown on this map had been laid by 1910 to connect Spring Mill Print Works with what continued to be known as Broadley Stone Siding loading bank. It is not known when the tramway ceased to be used, but the siding and loading bank closed in 1955/56.

From 1886 until c1900 Broadley Stone Siding was the point where stone, brought down from the moors to the west on a tramway, was then shaped and dispatched via the Facit Branch. The course of the tramway can be inferred from the map as its cuttings and embankments remain in place, for example close to field number 886.901.

Tonacliffe Mill

In 1845 Tonacliffe Mill was a water powered pollen fulling mill. Fulling is the process used to remove all natural oils from the cloth and involved soaking the cloth in stone tanks of urine and then putting the fabric under pressure to create a dense fabric that was used for coats. There was a row of mill houses, built for the millworkers, adjacent to the mill, but these were destroyed by flooding in 1925. Theses houses were rebuilt by Whitworth Council and demolished in the 1960’s.

Old Mills of Heywood

Click here for more information.

Quarrying

Ding Quarry

Farming

Daniel Fold Farm circa 1960.

Harper Road Farm.

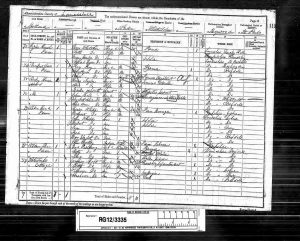

This 1891 census shows the Whipp family living at Naden Head farm. They moved from there into Lanehead village where they lived until 2014.

Munitions

Great War Munitions Production in Rochdale

WWII Healey Dell Munitions Factory

Railway

W.D. 90535 Works a weedkiller train along the Whitworth branch, formerly the Rochdale to Bacup line. A scene from Telerail, The Richard Greenwood Collection North West England.

Other Resource

Grace’s Guide to British Industrial History – Samual Heap & Son Ltd.

Archives Hub – To find unique sources for your research – Samual Heap & Son Ltd.

The National Archives – Samual Heap & Son Ltd.